Using Precision Agriculture for Fruit Ripeness Detection

As part of this research program, Malaysia Flying Labs seeks to apply advanced robotics to the black bunch count method of detecting fruit ripeness.

August 19th, 2024

The collaborative research program undertaken by Flying Labs Malaysia, Asia Pacific University (APU) for Innovation and Technology, and KLK (Kuala Lumpur Kepong) Plantations Berhad represents a significant advancement in precision agriculture, focusing on the development of an innovative undercanopy black bunch count system for oil palm fruit ripeness detection. This initiative aims to address one of the critical challenges in the oil palm industry: accurately determining the optimal harvest time to maximize yield and quality while minimizing waste.

Oil palm fruit ripeness is a key factor in determining oil yield and quality. Traditionally, assessing fruit ripeness has relied heavily on visual inspection by skilled workers. However, this method is subjective and labor-intensive, leading to inconsistencies and inefficiencies. The research program seeks to revolutionize this process through the application of advanced robotics and computer vision technologies, specifically targeting the "black bunch count" – a method used to identify ripe fruit bunches that have darkened due to the natural ripening process.

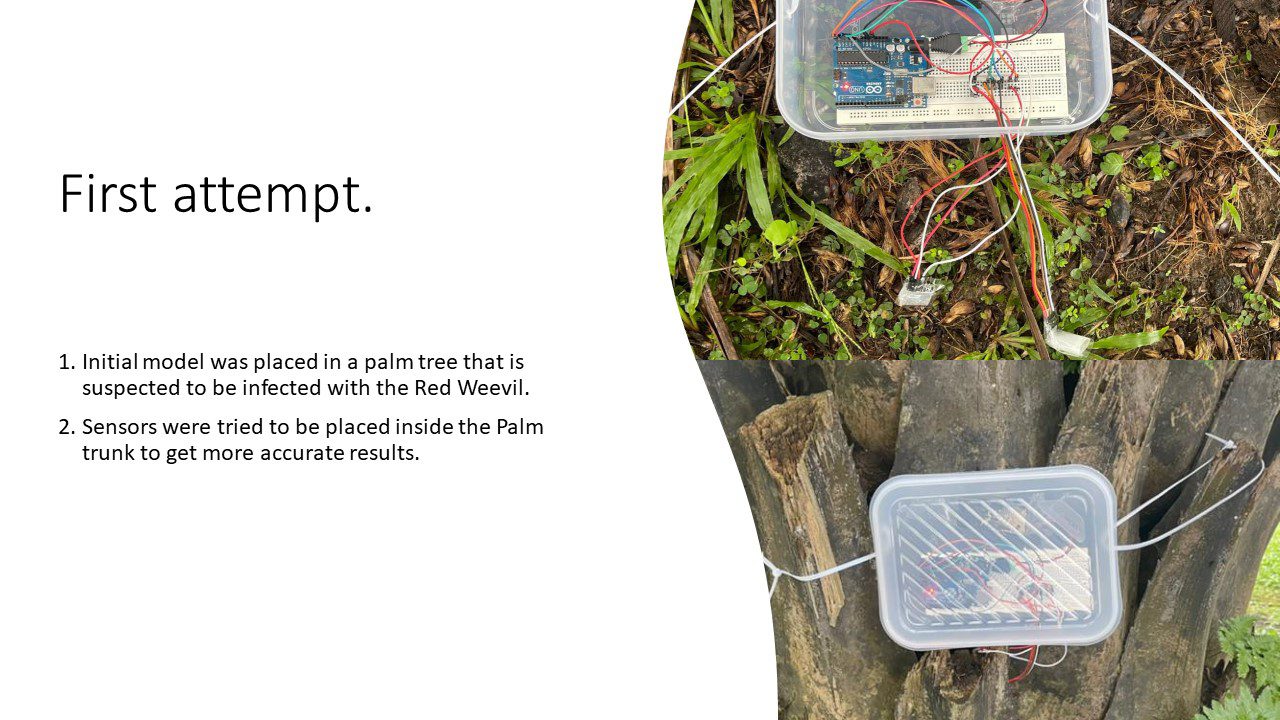

Flying Labs Malaysia, known for its expertise in robotics and drone technology, plays a pivotal role in this project. The team has been working on developing a robotic system capable of navigating the challenging undercanopy environment of oil palm plantations. This system is equipped with high-resolution cameras and advanced sensors that can capture detailed images and data from the fruit bunches hidden beneath the canopy. The goal is to create a reliable and autonomous solution that can accurately count the ripe bunches without human intervention.

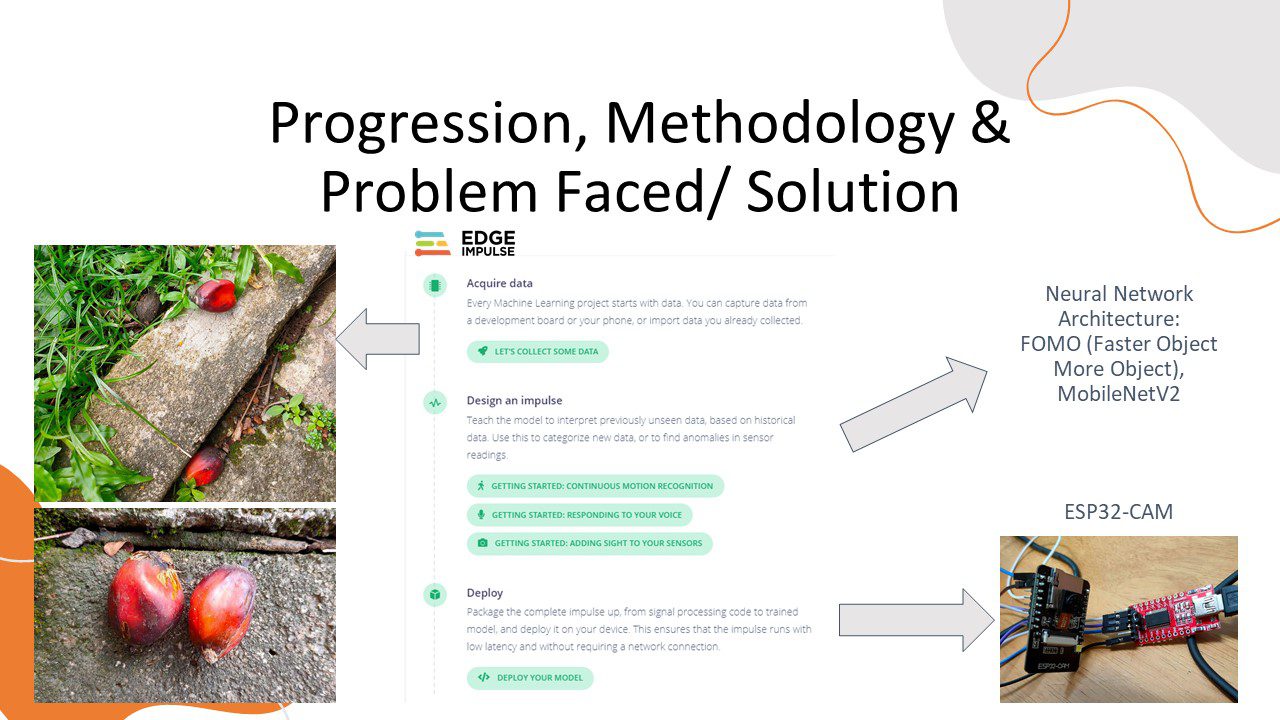

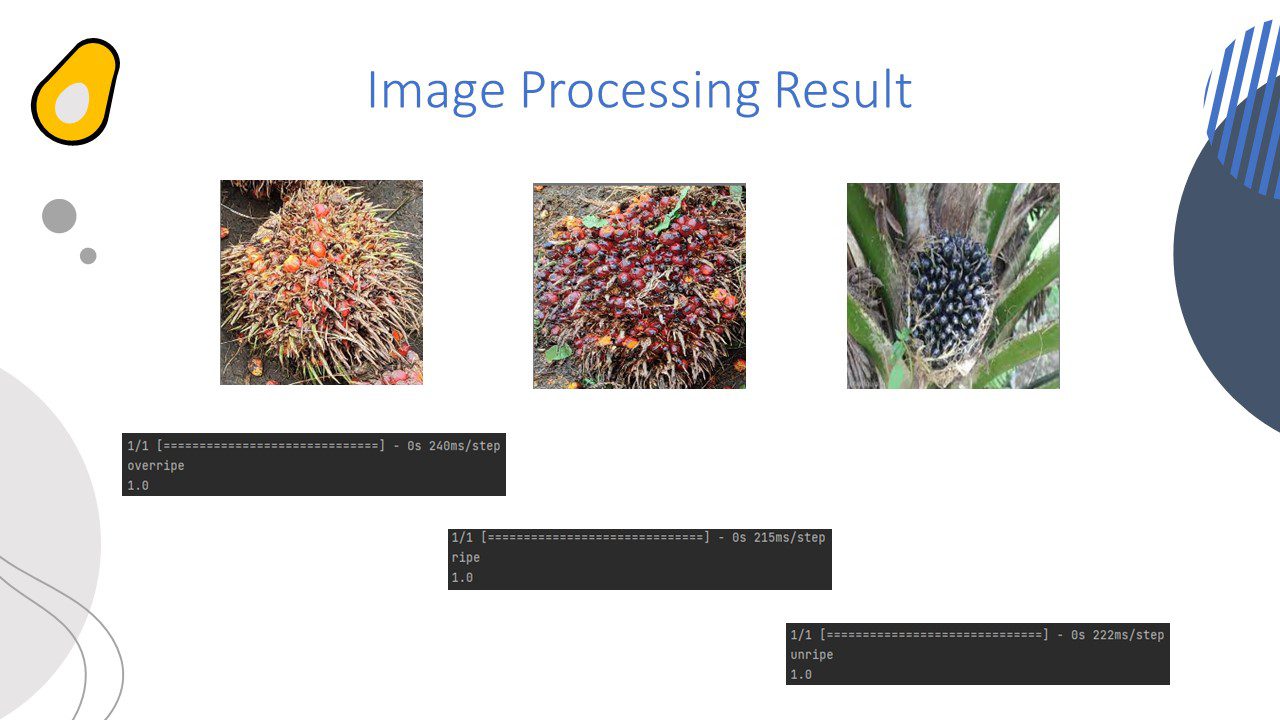

Asia Pacific University (APU) contributes its expertise in artificial intelligence and data analytics to the project. APU researchers are developing sophisticated algorithms to analyze the data collected by the robotic system. These algorithms use machine learning techniques to distinguish between ripe and unripe fruit bunches based on color, texture, and other visual cues. The data collected is then processed to provide real-time information on fruit ripeness, enabling plantation managers to make informed decisions about harvesting.

KLK Plantations, one of Malaysia's leading palm oil producers, provides the practical setting and industry insights for this research. By testing the technology in real-world conditions, KLK ensures that the system is not only scientifically sound but also economically viable. The company's participation helps align the research objectives with industry needs, ensuring the development of a practical tool that can be seamlessly integrated into existing agricultural practices.

The collaboration has yielded promising results. Initial trials have shown that the undercanopy black bunch count system can accurately identify ripe fruit bunches, with a precision that surpasses traditional methods. This technology not only improves the accuracy of ripeness detection but also reduces labor costs and increases the efficiency of the harvesting process. By enabling more precise timing of the harvest, the system helps optimize oil extraction rates and improve the overall quality of the palm oil produced.

Furthermore, the adoption of this technology aligns with broader sustainability goals. By reducing the need for manual labor and minimizing the harvesting of unripe fruit, the system contributes to more sustainable agricultural practices. It also supports better resource management, as plantation managers can plan harvesting operations more effectively, reducing waste and improving productivity.

Furthermore, the adoption of this technology aligns with broader sustainability goals. By reducing the need for manual labor and minimizing the harvesting of unripe fruit, the system contributes to more sustainable agricultural practices. It also supports better resource management, as plantation managers can plan harvesting operations more effectively, reducing waste and improving productivity.

In conclusion, the research program on undercanopy black bunch count for oil palm fruit ripeness detection is a pioneering effort that combines cutting-edge robotics, AI, and industry expertise. This collaboration between Flying Labs Malaysia, APU, and KLK Plantations demonstrates the potential of technology to transform traditional agriculture, making it more efficient, precise, and sustainable. As the project progresses, it holds the promise of setting new standards in the oil palm industry and beyond, showcasing the power of innovation in addressing complex agricultural challenges.

Category(s)

Location(s)

Recent Articles

View All »

Team Cameroon's Road to Victory at the First Global Robotics Competition 2025